Brushes are an essential tool that have been used for centuries to achieve precise and consistent results in a variety of applications. Brushes have been used for thousands of years, with evidence of brush-like tools dating back to ancient civilizations in Egypt, China, and Greece. The first brushes were likely made from natural materials like animal hair, plant fibers, and feathers, and were used for a variety of tasks such as painting, writing, and cleaning. Read More…

Gordon Brush® is an ISO 9001:2015 certified manufacturer of standard & specialty brushes for the commercial, aerospace, military, medical & electronics industries.

Spiral Brushes manufactures industrial brushes, custom brushes, power brushes, wire brushes, conveyor cleaning brushes, steel brushes, stainless steel brushes, brass brushes, nylon brushes, abrasive nylon brushes, and natural fiber brushes.

The Industrial Brush Co. is a provider of brushes. Since 1946, we have been committed to providing high quality brushes and customer service for a variety of industrial applications and marketplaces.

Justman Brush is an ISO 9001:2015 Registered Manufacturer centrally located in the United States. We manufacture brushes for a large variety of industrial applications for our customers in the industrial, aerospace, military, laboratory & scientific, medical and food service industries. With over 91 years of manufacturing experience, we have the American Quality, competitive pricing and short...

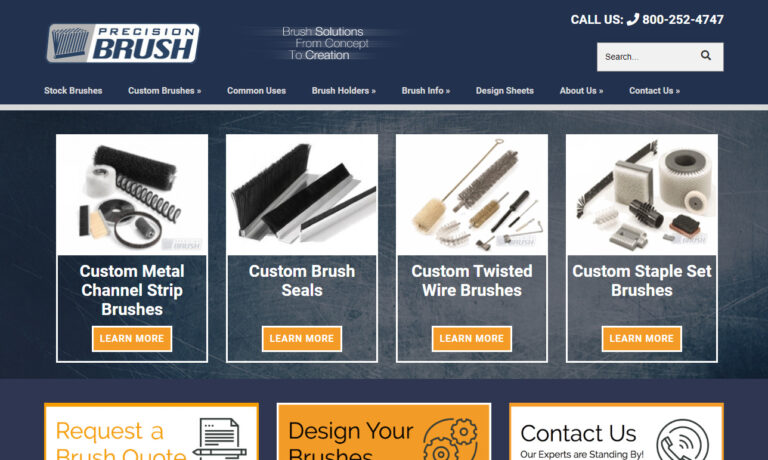

Precision Brush Company is an industry leader that has the technology, expertise and experience to satisfy all of your brush requirements.

Braun Brush is committed to manufacturing quality brushes using a variety of methods. We offer convenient purchasing of the most extensive brush line available & a unique design-your-own brush service on the web.

For over 30 years, Tanis has been a leading brush manufacturer. Tanis has put innovation to work in everything we do, using the latest technology, materials, manufacturing advancements and engineering expertise.

More Brush Manufacturers

The History of Industrial Brushes: Powering Progress

Industrial brushes are indispensable components in a wide array of manufacturing, processing, and maintenance applications. Their long history reflects the ongoing evolution of industrial technology and the pursuit of efficiency in material handling, cleaning, and finishing processes. Understanding the development of industrial brushes is essential for buyers seeking high-performance solutions for specialized needs.

From the earliest days of human civilization, people crafted simple brushes from locally available materials—sticks, straw, animal hair—to tackle everyday cleaning and processing tasks. Ancient societies used brushes for grain threshing, pottery smoothing, and textile production, laying the groundwork for today’s industrial brush applications.

The Industrial Revolution (circa 1760–1840) marked a seismic shift in brush technology. As mechanization transformed manufacturing, the demand for reliable, durable tools surged. Early industrial brushes, typically handmade and constructed from hog bristles or horsehair fixed to wooden handles or bases, became essential in emerging industries. Textile mills relied on carding brushes to separate wool fibers, while metalworking shops used wire brushes to deburr and clean metal edges.

The advent of the steam engine and powered looms introduced new challenges, leading to the adoption of tougher materials such as steel and brass wire by the mid-1800s. These wire brushes, often twisted into frames or fashioned into rotary wheels, were crucial for removing rust, scale, and contaminants in steel production and heavy manufacturing.

By the late 19th century, mass production revolutionized brush manufacturing. Renowned companies like Osborn (founded in Britain in 1887) and Felton Brush (USA) standardized designs, introducing rotary brushes for assembly lines and large-scale cleaning systems. The proliferation of electricity spurred further innovation—motorized brush systems appeared for cleaning conveyor belts, polishing metal components, and even sorting agricultural crops.

Throughout the early 20th century, industrial brushes became integral to sectors such as automotive assembly, shipbuilding, and mining. Specialized designs emerged: strip brushes for sealing, cylinder brushes for industrial sweeping, and abrasive brushes for surface finishing. The introduction of synthetic materials like nylon (invented in 1935) ushered in an era of enhanced durability, chemical resistance, and versatility.

Today, industrial brushes are engineered with advanced polymers, high-performance abrasives, and precision manufacturing techniques to serve industries as diverse as aerospace, electronics, food processing, and renewable energy. Whether deburring turbine blades, cleaning high-efficiency solar panels, or maintaining pharmaceutical clean rooms, these tools have evolved in tandem with industrial progress—adapting seamlessly to new machinery, materials, and regulatory standards.

Types of Brushes: Comprehensive Guide for Industrial and Commercial Applications

Selecting the right brush depends on application-specific requirements, such as material compatibility, durability, and cleaning or finishing effectiveness. Below, we outline the most common types of brushes, highlighting their construction, materials, and typical uses across industries.

- Natural Fiber Brushes: Manufactured from animal hair (e.g., horsehair, boar bristle) or plant fibers (e.g., broomcorn), these brushes excel at holding water, cleaning solutions, and delicate polishing. They are ideal for fine surface finishing, dusting, and tasks demanding gentle contact.

- Synthetic Fiber Brushes: Made from nylon, polyester, polypropylene, or other engineered filaments, synthetic brushes deliver exceptional durability and resistance to chemicals, solvents, and abrasive materials. They are suited for high-volume industrial processes and harsh environments where longevity and resilience are paramount.

Popular Industrial Brush Types

- Strip Brushes: Featuring a flexible backing strip—typically plastic or metal—strip brushes can conform to a range of profiles and shapes. Bristles may be nylon, polypropylene, or natural fiber, tailored for specific tasks. Applications: Sealing gaps in machinery, dusting conveyor belts, preventing debris buildup, and static control in electronics production.

- Spiral Brushes: Constructed by winding bristles around a central core, spiral brushes deliver uniform contact for cleaning or polishing irregular surfaces. Materials include steel, brass, nylon, and natural fibers. Applications: Deburring 3D-printed parts, jewelry cleaning, bottle washing, and internal pipe cleaning.

- Brooms: These industrial cleaning brushes are available with both natural and synthetic bristles, brooms are a staple for sweeping dirt, dust, and debris in indoor and outdoor settings. Applications: Floor cleaning in warehouses, construction sites, workshops, and for snow removal.

- Roller Brushes: Featuring a cylindrical core densely packed with bristles, roller brushes excel at continuous cleaning and material handling. Common bristle materials include nylon, polyester, and natural fibers. Applications: Carpet and upholstery cleaning, coating and adhesive application, as well as in printing and textile manufacturing.

- Wire Brushes: Utilizing bristles made from steel, brass, or stainless steel wire, these brushes are designed for aggressive cleaning, rust removal, and surface preparation. Applications: Metal fabrication, welding, shipbuilding, and maintenance of heavy equipment.

- Tube Brushes: Flexible and often featuring a twisted-in-wire design, tube brushes are engineered to clean the inner surfaces of pipes, rollers, and other cylindrical equipment. Applications: Pipe cleaning, food processing equipment maintenance, and laboratory glassware cleaning.

- Cylinder Brushes: More rigid than tube brushes, cylinder brushes offer robust cleaning and deburring for conveyor belts, rollers, and industrial machinery. Applications: Debris removal, dust control, and preparation of surfaces for finishing.

- Cleaning Brushes: Encompassing a broad category, these brushes range from hand-held scrubbers to industrial floor machines. Bristle selection (nylon, polyester, natural fiber) depends on the cleaning environment. Applications: Commercial kitchens, medical facilities, automotive detailing, and janitorial services.

- Bottle Brushes: Featuring a long handle and a small cylindrical head, bottle brushes are specifically designed for cleaning narrow-mouthed containers. Bristles are typically nylon or other synthetic materials. Applications: Cleaning bottles, flasks, laboratory glassware, baby bottles, and reusable straws.

Specialty and Custom Brushes

Modern brush manufacturers also offer specialty and custom brushes tailored to unique industrial challenges. Whether you need micro brushes for semiconductor fabrication, static control brushes for electronics assembly, or food-grade brushes for hygienic processing, there are solutions designed for your exact specifications.

Brushes Compared to Other Cleaning Utensils

When evaluating cleaning solutions for industrial, commercial, or residential use, understanding the unique advantages of brushes over other cleaning utensils is crucial for making informed purchasing decisions.

- Targeted Cleaning: Bristles or filaments penetrate crevices, corners, and textured surfaces, ensuring debris is dislodged from hard-to-reach areas where mops, sponges, or cloths may fall short.

- Versatility: Brushes are available in a multitude of types, sizes, and materials, enabling them to tackle a vast range of cleaning tasks—from heavy-duty industrial scrubbing to delicate surface dusting.

- Ergonomic Designs: Many professional brushes feature handles engineered for comfort and grip, minimizing user fatigue and improving productivity during extended cleaning sessions.

- Sustainability: Unlike single-use wipes or disposable pads, most industrial and commercial brushes are reusable and built for longevity, reducing both waste and replacement costs.

However, users must consider potential limitations. Stiff-bristled brushes may scratch sensitive surfaces, and brushes often require meticulous cleaning to prevent microbial buildup—particularly in food and medical settings. For wide-area cleaning, such as mopping large floors, brushes may be less efficient than sweepers or floor scrubbers. Regular maintenance and appropriate selection of brush type can mitigate these downsides.

What Have Been the Advancements in Industrial Brushes?

Curious about how modern industrial brushes outperform their predecessors? Explore the latest innovations in brush technology and see how these advancements can optimize your operations.

- Material Innovations

- Synthetic Fibers: The introduction of nylon in the 1930s set the stage for robust, chemical-resistant brushes. Today’s synthetic options—polyester, polypropylene, and abrasive-infused filaments (such as silicon carbide or diamond)—enable brushes to withstand harsh environments and deliver superior performance in tasks like deburring and finishing.

- Advanced Metals: With the evolution of stainless steel and corrosion-resistant alloys, wire brushes can now endure extreme temperatures and aggressive chemicals, making them indispensable in aerospace, marine, and heavy manufacturing.

- Composite Constructions: Hybrid brushes combine metallic cores with polymer coatings, balancing strength and flexibility for delicate yet demanding operations such as cleaning sensitive electronics or medical equipment.

- Manufacturing Techniques

- Automation and Precision: Computer-controlled (CNC) machinery and robotic assembly lines now produce brushes with consistent bristle density and uniformity, essential for high-speed, automated production environments.

- Twisted-in-Wire Design: Invented in the early 20th century, this method creates durable tube and wheel brushes for internal cleaning and aggressive surface preparation. Ongoing refinements ensure reliability and performance in challenging industrial settings.

- Modular Systems: Modern brushes often feature replaceable bristle sections or universal mounts, minimizing downtime for maintenance in industries such as automotive manufacturing or food processing.

- Application-Specific Advancements

- Abrasive Brushes: By embedding abrasives directly into bristle materials, these brushes can polish, grind, and finish surfaces in a single step, streamlining workflows in metalworking, woodworking, and advanced manufacturing.

- High-Speed Compatibility: Engineers have developed balanced brush designs that withstand extreme rotational speeds (RPMs) in CNC machines and robotic arms, minimizing vibration and enhancing both safety and precision.

- Specialized Shapes: Innovations such as strip, coil, and encapsulated brushes now serve niche applications—sealing machinery gaps, cleaning solar panels, or eliminating static in electronics manufacturing.

- Technological Integration

- Smart Brushes: Some advanced models include embedded sensors to monitor bristle wear, pressure, or cleaning effectiveness. These features are particularly valuable in automated or remote-monitored production environments, where predictive maintenance can prevent costly downtime.

- Eco-Friendly Designs: With increasing emphasis on sustainability, brush manufacturers are introducing biodegradable filaments, recycled plastics, and modular systems that extend product life and reduce landfill waste.

Impact

These technological breakthroughs have expanded the functionality, precision, and durability of industrial brushes. Today’s solutions support advanced manufacturing, aerospace, 3D printing, food processing, and more—delivering performance that far surpasses traditional, manual brushes.

Advancements in Brushes: Meeting Evolving Industry Needs

To stay competitive, brush manufacturers continuously enhance their products by addressing existing limitations and exploring new frontiers in performance. Here’s what’s driving progress:

- Advanced Materials: New synthetic fibers and composite materials offer unmatched durability, flexibility, and cleaning power. These innovations ensure brushes retain their effectiveness over prolonged use, even in harsh industrial environments.

- Antimicrobial Properties: Incorporation of antimicrobial agents into bristle materials inhibits bacterial growth, reducing the risk of cross-contamination—an essential feature for medical, pharmaceutical, and food production applications.

- Self-Cleaning Designs: Some modern brushes feature self-cleaning mechanisms or easy-to-disassemble components, making maintenance more efficient and minimizing downtime.

- Customization and Modularity: Interchangeable brush parts allow end-users to replace worn bristles or adapt brushes to new tasks, maximizing ROI and reducing material waste.

- Sustainability Initiatives: Eco-friendly manufacturing processes, recycled materials, and biodegradable options are increasingly available, aligning with corporate sustainability goals and regulatory requirements.

By focusing on these priorities, brush manufacturers are delivering high-performance, long-lasting, and environmentally conscious products for a rapidly changing global market.

Choosing the Proper Brush for Your Application

Selecting the right industrial or commercial brush is critical for achieving optimal results and minimizing operational costs. Here are key factors to consider:

- Application Purpose: Define the specific task—cleaning, surface finishing, painting, sealing, or deburring—to narrow your options.

- Surface Material: Use soft bristles for delicate surfaces (e.g., glass, polished metal) to avoid scratches, and stiffer bristles for robust materials (e.g., steel, concrete) requiring aggressive action.

- Area Size and Shape: Ensure the brush can effectively reach all necessary areas. For tight spaces or complex geometries, consider specialized brushes such as tube, spiral, or custom-shaped designs.

- Chemical Compatibility: Select bristle and backing materials that resist degradation from any chemicals, solvents, or cleaning agents involved in your process.

- Durability and Maintenance: Evaluate brush construction quality, bristle retention, and ease of cleaning or replacement to ensure sustained performance and lower total cost of ownership.

- User Comfort and Ergonomics: For manual tasks, prioritize brushes with ergonomic handles, non-slip grips, and adjustable settings to reduce fatigue during prolonged use.

- Supplier Reputation and Support: Seek out recommendations, customer reviews, and technical support from established suppliers to inform your purchasing decision.

Ready to find the perfect brush for your needs? Explore our comprehensive directory of leading brush manufacturers and request quotes from multiple suppliers with ease.

The Future of Brushes: Trends, Predictions, and Buyer Considerations

The future of industrial and commercial brushes will be shaped by rapid technological innovation, sustainability imperatives, and the unique challenges of emerging industries. As buyers consider investments in cleaning and surface preparation equipment, staying informed about these trends is essential.

- Smart Technology and Automation

- IoT Integration: Expect more brushes equipped with embedded sensors for real-time monitoring of wear, pressure, and cleaning efficacy. Connected to manufacturing or facility management systems, these smart brushes will help optimize maintenance and reduce unplanned downtime.

- AI-Driven Optimization: Artificial intelligence may soon enable brushes to automatically adjust bristle stiffness, speed, or cleaning patterns based on feedback from the working surface—perfect for highly specialized or delicate applications in electronics, aerospace, or medical device manufacturing.

- Advanced Materials

- Nanotechnology: Nano-coated or nano-infused bristles will deliver unprecedented durability, self-cleaning capabilities, and heat resistance—ideal for extreme environments and next-generation manufacturing.

- Bio-Based and Biodegradable Filaments: Driven by regulatory demands and customer preference, more brushes will utilize plant-derived polymers and recyclable components, supporting green manufacturing and circular economy initiatives.

- Composite and Hybrid Designs: Expect further integration of ceramics, carbon fibers, and advanced synthetics to address specialized needs in electric vehicle production, renewable energy, and aerospace.

- Sustainability Focus

- Circular Product Design: Brushes will increasingly be engineered for easy disassembly, recycling, and re-use. Replaceable bristle modules and recyclable cores will become standard in response to stricter environmental regulations.

- Energy-Efficient Manufacturing: Lightweight, durable designs will minimize energy consumption during use—particularly important for high-speed, automated cleaning systems.

- Industry-Specific Evolution

- Additive Manufacturing: Brushes designed for 3D printing post-processing will refine intricate parts without damage, while miniaturized brushes will serve nanotechnology and semiconductor industries.

- Renewable Energy: Specialized brushes will clean and maintain solar panels, wind turbine blades, and hydrogen fuel cells, supporting the growth of the clean energy sector.

- Micro-Applications: Tiny, precision-engineered brushes will enable new capabilities in electronics assembly, biotechnology, and medical device cleaning.

Outlook

By 2030 and beyond, industrial brushes will be smarter, more sustainable, and highly specialized—quietly driving progress in manufacturing, clean technology, and beyond. As a buyer, staying ahead of these trends ensures you invest in solutions that deliver efficiency, compliance, and long-term value.

Manufacturers are rising to the challenge with ongoing R&D, introducing brushes with improved bristle arrangements for superior control and performance. Smart technologies, including embedded sensors and automated systems, will further expand the possibilities of brush-based cleaning and surface preparation. Eco-friendly options using recycled or biodegradable materials are rapidly becoming the new standard.

Looking for the best brush supplier for your unique requirements? Our directory provides detailed profiles of top brush manufacturers, including contact forms for direct inquiries and quote requests. Our exclusive previewer lets you quickly assess each company’s specializations, while our streamlined RFQ form enables you to reach multiple suppliers with a single request—perfect for efficient sourcing and comparison.

Are you ready to modernize your cleaning, finishing, or manufacturing process with advanced industrial brushes?

Explore our comprehensive brush manufacturer listings or learn more about clean room cleaning solutions to discover the right tools for your business.

What are industrial brushes and why are they important in manufacturing?

Industrial brushes are tools used in manufacturing, processing, and maintenance to clean, finish, or process various materials. Their importance lies in their ability to efficiently handle tasks like removing contaminants, polishing surfaces, finishing edges, and cleaning equipment, which boosts productivity and product quality in industries ranging from automotive and metalworking to food processing and electronics.

How have industrial brushes evolved over time?

Industrial brushes have evolved from simple, handmade tools using natural fibers and wooden handles to advanced equipment constructed with synthetic polymers, metallic wires, and composite designs. Innovations such as wire brushes, rotary systems, CNC-manufactured brushes, and the use of abrasion-resistant and antimicrobial materials now allow for greater durability, precision, and versatility in demanding industrial applications.

What are the main types of industrial brushes and their typical applications?

Common industrial brush types include strip brushes (for sealing and dust control), spiral brushes (for cleaning irregular surfaces), brooms (for sweeping floors), roller brushes (for material handling), wire brushes (for rust removal and surface prep), tube brushes (for cleaning pipes), and bottle brushes (for cleaning containers). Each is designed with specific bristle materials and shapes according to its intended use across industries like manufacturing, cleaning, and food processing.

How do brushes compare to other cleaning utensils?

Brushes offer targeted cleaning by penetrating crevices and textured surfaces better than mops or sponges. They are highly versatile, reusable, and can be made for gentle or heavy-duty jobs. However, stiff brushes may scratch sensitive materials and require regular cleaning to prevent microbes. For wide-area cleaning, other options like sweepers or floor scrubbers may be more efficient.

What innovations have improved modern industrial brushes?

Recent advancements include the development of synthetic and composite bristles, antimicrobial and self-cleaning properties, CNC and robotic manufacturing for greater precision, abrasive-filled and high-speed-compatible brushes, modular and customizable designs, and even smart brushes with embedded sensors for monitoring wear and performance.

What factors should be considered when choosing the right industrial brush?

Key factors include the application purpose (cleaning, finishing, deburring), material and surface compatibility, area size and reach, chemical resistance, durability, ease of maintenance, ergonomic features, and the supplier’s reputation and support. Custom and specialty brushes may be necessary for unique or highly specific uses.

What trends are shaping the future of industrial brushes?

Future trends include the integration of smart and IoT-ready brushes with sensors, use of nanotechnology and biodegradable materials, customizable and modular design for easy recycling, adaptation to new industries such as additive manufacturing and renewable energy, and eco-friendly production to meet sustainability goals.

Brooms

Brooms Brushes

Brushes Static Eliminator

Static Eliminator Sweepers

Sweepers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services