Tube brushes are used in plumbing and other equipment maintenance and cleaning applications to clean tubes or difficult-to-reach places. In some cases, using a tube brush to clean the tube is sufficient to clear the clog and restore a consistent flow in commercial or domestic plumbing. A plumber typically starts with this approach before getting a trickier fix. Read More…

Gordon Brush® is an ISO 9001:2015 certified manufacturer of standard & specialty brushes for the commercial, aerospace, military, medical & electronics industries.

Spiral Brushes manufactures industrial brushes, custom brushes, power brushes, wire brushes, conveyor cleaning brushes, steel brushes, stainless steel brushes, brass brushes, nylon brushes, abrasive nylon brushes, and natural fiber brushes.

The Industrial Brush Co. is a provider of brushes. Since 1946, we have been committed to providing high quality brushes and customer service for a variety of industrial applications and marketplaces.

Justman Brush manufactures a large variety of tube brushes for industrial, food service, laboratory & scientific applications. We stock a large selection of industrial black nylon tube brushes as well as an even larger selection of in stock color-coded food grade tube brushes with polyester filaments. We also offer extensive options for custom tube brush options, including single or double stem...

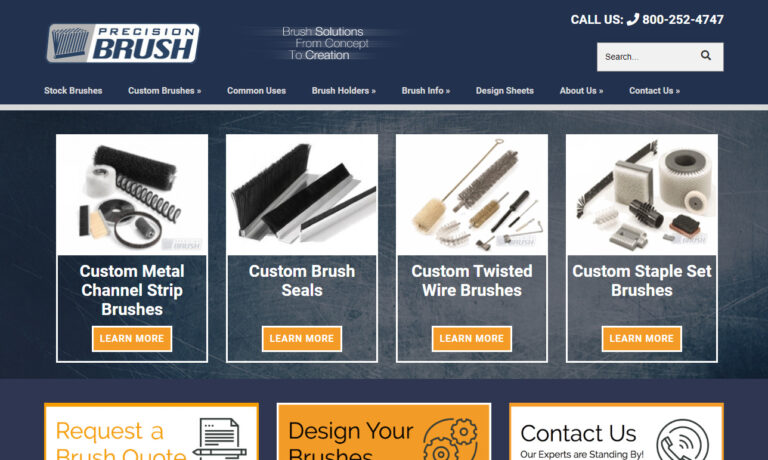

Precision Brush Company is an industry leader that has the technology, expertise and experience to satisfy all of your brush requirements.

Braun Brush is committed to manufacturing quality brushes using a variety of methods. We offer convenient purchasing of the most extensive brush line available & a unique design-your-own brush service on the web.

For over 30 years, Tanis has been a leading brush manufacturer. Tanis has put innovation to work in everything we do, using the latest technology, materials, manufacturing advancements and engineering expertise.

More Tube Brush Manufacturers

In recycling facilities, tube brushes are also employed as a component of an automated cleaning system to thoroughly clean bottles and other containers that will be put to use again. These brushes are hooked to a machine that rotates them at high speeds rather than having a handle on the end.

To clean drain pipes and other bends, most plumbers utilize tube brushes with a certain amount of flexibility. A flexible brush can follow the contours of any shape and bend with them.

With the drill's fast spin, the tube brush is instantaneously transformed into a highly- effective cleaning instrument. Several materials may be used to create tube brushes for mild to high-duty applications. Wire-bristle brushes work best for removing heavy debris and contaminants because they may scrape a tube's walls and provide enough friction to clear any obstacles.

Materials Used

- The bristles of the tube brush might be metal, nylon, or abrasive.

- In twisted-in-wire brushes, the stem wire is often made of galvanized steel, stainless steel, or, in certain circumstances, brass or aluminum wire.

- The diameter of the stem wire, which is used to twist the filament into the brush, is known as the stem gauge.

- Standard fillers include synthetics, natural fibers, and wires for twisted-in-wire brushes.

Types of Tube Brushes

There are several other types of tube brushes.

- Single-Stem Brush: Has a single continuous length of stem wire made of galvanized steel and a constructed eye loop for easy handling. The most efficient usage of a single stem, single spiral tube brush is for manual or hand cleaning tasks. The ID may be manually inserted with ease because of the single spiral of straight wire fill.

- Double-Stem Single-Spiral Brush: Filaments are wound around two stem wires on each side of four stem wires that form the brush's stems. As a result, the brush has a much stronger foundation and could have more filaments.

- Side-Action Brush: A side-action brush offers a high level of stiffness and a sturdy stainless-steel stem. Used with sensitive surfaces. While the gap between the brushes allows for the escape of dirt, chips, and burrs, the two rows of tightly- packed bristles are intended to clean threaded tubes effectively. There is no trash left behind by the bristles.

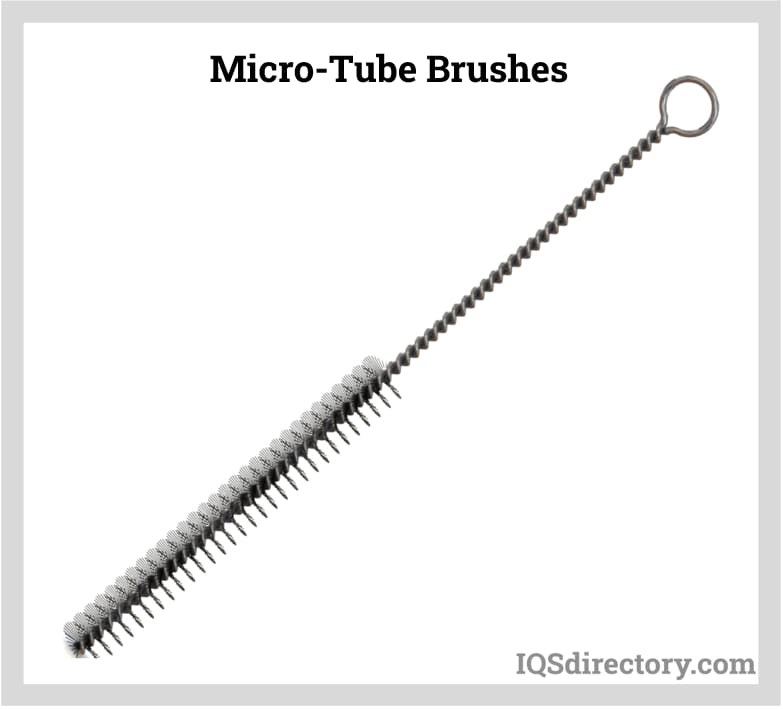

- Micro-Tube Brushes: As the name implies, these brushes are used to clean, ream, and deburr a variety of tiny holes, tubes, and cavities. Despite their miniature size, they are strong and incorporate a finger loop for comfort.

- Tube Brushes with Spiral Patterns: These are frequently constructed of synthetic materials and often have an attachment on the head so they may be used with power drills.

Construction of Tube Brushes

- The handle is the first factor to be considered while building a brush. The material must be solid and durable to retain the bristles in place while enduring constant use.

- Bristles are inserted between stem wires to create twisted wire brushes. Various metals, including copper, brass, bronze, beryllium, and aluminum, can be used to create the wire.

- The handle is molded to take on the final shape of the finished brush.

- After that, more features can be added, such as a loop on top for storage and handling, groves or indentations for a better grip, or sunken bristles.

- The efficacy and durability of the brush selected for a project depend significantly on how the bristles are inserted, the material used for the bristles, and the diameter of the bristles themselves.

- Many tube brushes are built with a looped end for hanging.

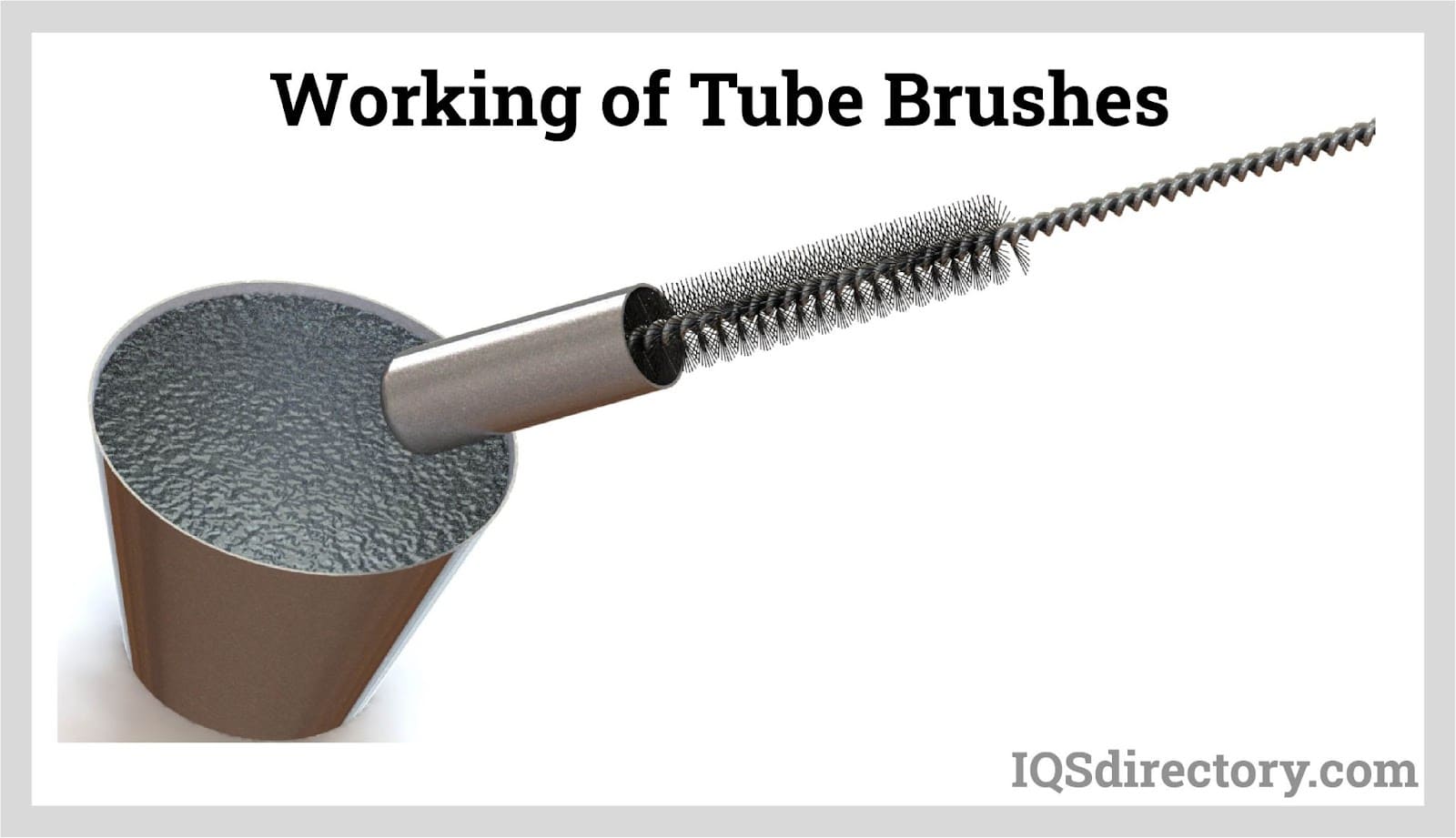

Working of Tube Brushes

- A long, thin piece of metal that may be put deeply into a long tube which is attached to a tube brush.

- The brush's diameter should ideally be at least as large as the tubes.

- When the brush wires are twisted or moved up and down, they will press up against the tube walls and remove any debris or other accumulation.

Benefits of Tube Brushes

- Tube brushes reduce costs related to removing crusty buildup on equipment.

- They reduce the operations' downtime to a minimum.

- No mechanical or chemical cleaning is required.

- Tube brushes extend the equipment's lifespan.

- They reduce surface condensers' use of fossil energy.

Applications of Tube Brushes

Tube brushes work well for interior cleaning and deburring tasks such as:

- Deburring cross holes

- Cleaning and deburring inner threads, such as those in tapped holes

- Cleaning bore and passage surfaces of accumulated foreign material, such as paint and coatings

- Cleaning tubing and pipe polishing

- Cleaning interior slots, keyways, and grooves of chips and burrs

- Internal cleaning and deburring of machined passageways

- Drills, drill presses, and other low-speed equipment all have been adapted to function as tube brushes.

Choosing the Proper Tube Brushes Supplier

To make sure you have the most constructive outcome when purchasing Tube Brushes from a Tube Brushes Company, it is important to compare at least 4 Suppliers using our list of Tube Brushes companies. Each Tube Brushes Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Tube Brushes business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Tube Brushes businesses with the same form.

Brooms

Brooms Brushes

Brushes Static Eliminator

Static Eliminator Sweepers

Sweepers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services