Wire brushes are bristled surface treatment tools composed of a mounting area and a collection of many metal bristles. Wire brushes are used for a wide variety of surface treatment processes like abrasion and deburring and can be designed in many configurations. The two main categories into which most wire brush designs fit are hand held brushes and power brushes. Read More…

Gordon Brush® is an ISO 9001:2015 certified manufacturer of standard & specialty brushes for the commercial, aerospace, military, medical & electronics industries.

Spiral Brushes manufactures industrial brushes, custom brushes, power brushes, wire brushes, conveyor cleaning brushes, steel brushes, stainless steel brushes, brass brushes, nylon brushes, abrasive nylon brushes, and natural fiber brushes.

The Industrial Brush Co. is a provider of brushes. Since 1946, we have been committed to providing high quality brushes and customer service for a variety of industrial applications and marketplaces.

Justman Brush is an ISO 9001:2015 Registered Manufacturer centrally located in the United States. We manufacture brushes for a large variety of industrial applications for our customers in the industrial, aerospace, military, laboratory & scientific, medical and food service industries. With over 91 years of manufacturing experience, we have the American Quality, competitive pricing and short...

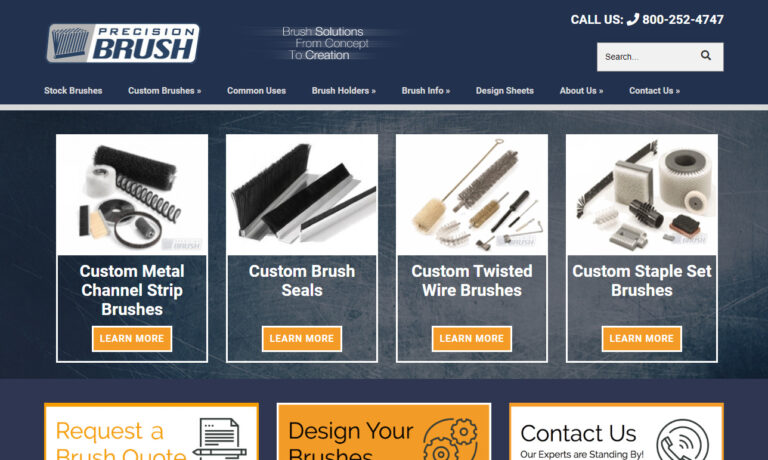

Precision Brush Company is an industry leader that has the technology, expertise and experience to satisfy all of your brush requirements.

Braun Brush is committed to manufacturing quality brushes using a variety of methods. We offer convenient purchasing of the most extensive brush line available & a unique design-your-own brush service on the web.

For over 30 years, Tanis has been a leading brush manufacturer. Tanis has put innovation to work in everything we do, using the latest technology, materials, manufacturing advancements and engineering expertise.

More Wire Brush Manufacturers

There are two types of wire brushes. Hand held wire brushes can be used for light duty cleaning, abrading and some deburring processes. Power wire brushes are used for the same purposes but are intended to make the process easier, less time consuming and more efficient.

There are many more machine operated wire brush configurations than there are hand brush configurations; hand brushes are only effective on a small scale and generally are not useful in heavy-duty surface treatment operations. Wire wheel brushes, cup brushes, end brushes and many other wire brush designs can be attached to motors that allow for brush rotation at variable speeds.

Paint and rust removal, deburring, buffing and other similar surface treatment processes become possible on a large scale when undertaken with power brushes.

Wire brush bristles can be crafted from a wide variety of metals. Brass, steel, stainless steel, bronze, aluminum, nickel silver, copper and titanium are all candidates for use as wire brush bristles. Each metal offers different qualities of abrasiveness, hardness, softness, durability, electrical and thermal conductivity and corrosion resistance, all of which must be taken into consideration in advance of a surface treatment process.

In the case of wheel brushes, cup brushes and end brushes, metal bristles are usually crimped in order to allow the wire to break cleanly as it wears, creating fresh new cutting edges. Some metals are more appropriate for this use than others.

Industrial parts manufacturers use wire power brushes to deburr and surface-condition metal, plastic, glass and wood parts, while other manufacturers and fabricators use wire scratch brushes and scrubbers for die, mold or tube cleaning and many other applications that require vigorous scrubbing.

Fine-bristled nickel silver and brass brushes are used for plating and polishing, and steel-bristled brooms are used for sweeping or scrubbing rough surfaces such as cement, stone, and street pavement as well as hard-to-reach ovens, brick and concrete.

Brooms

Brooms Brushes

Brushes Static Eliminator

Static Eliminator Sweepers

Sweepers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services